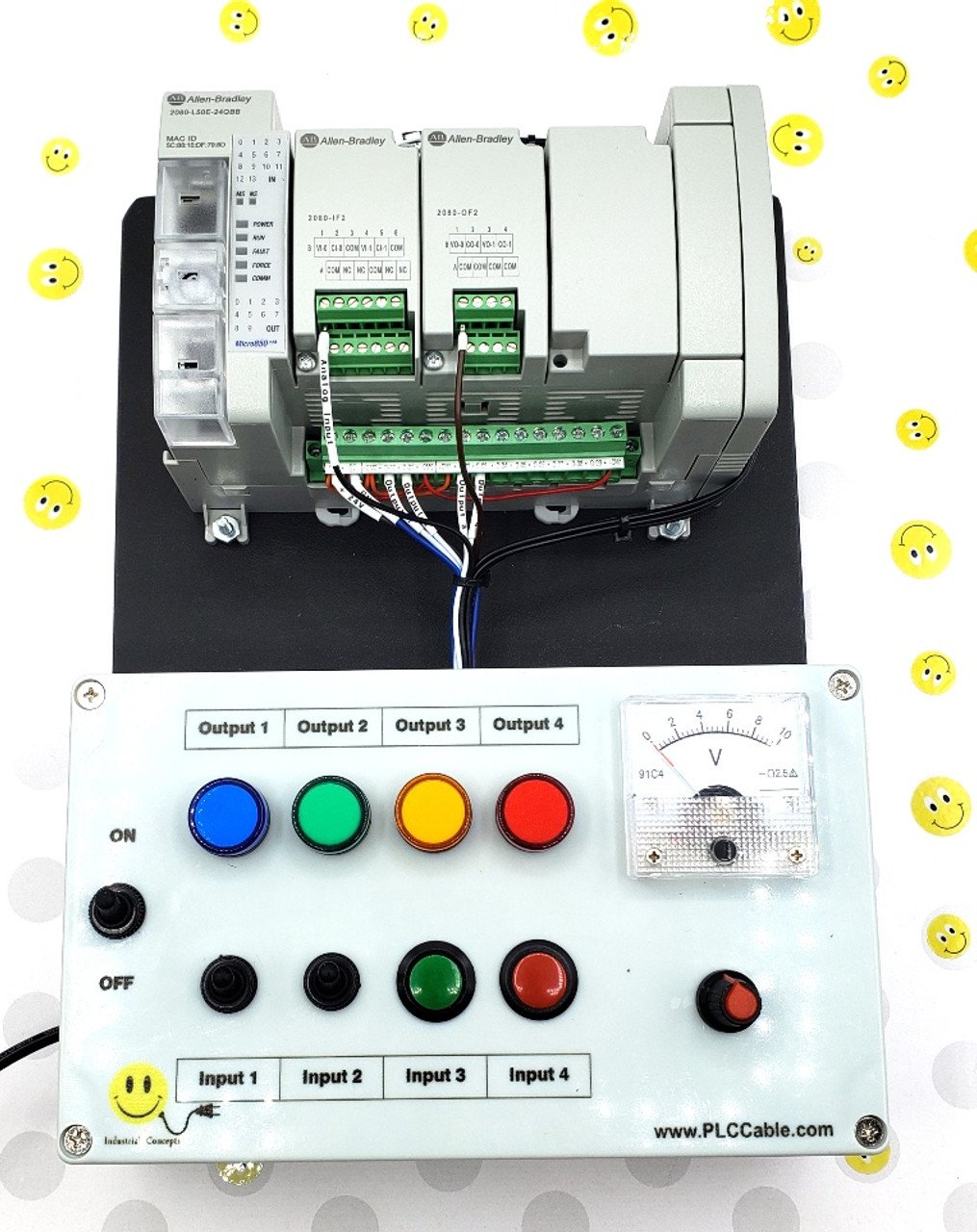

The 2080-L50E-24QBB programming software is an essential tool for users of the Allen-Bradley Micro850 series programmable logic controllers (PLCs). This comprehensive guide will delve into various aspects of the 2080-L50E-24QBB, including its features, setup, programming environment, and practical applications.

Overview of the 2080-L50E-24QBB

The 2080-L50E-24QBB is part of the Micro850 family, known for its flexibility and robust performance in industrial automation. This controller is equipped with Ethernet/IP capabilities, allowing for seamless integration into modern automation systems.

Key Features

- Input/Output Capabilities: Supports up to 14 24 VDC/VAC inputs and 10 source outputs.

- Communication Ports: Includes an embedded USB programming port and Ethernet port for easy connectivity.

- High-Speed Counters: Up to 4 high-speed counter channels for precise control applications.

- Expansion Options: Compatible with Point I/O and can support up to 132 I/O points through expansion modules.

Programming Environment

Connected Components Workbench (CCW)

The primary software used to program the 2080-L50E-24QBB is Connected Components Workbench (CCW). This software provides a user-friendly interface for developing, testing, and deploying control programs.

Installation of CCW

- Download the Software: Obtain CCW from the Rockwell Automation website or through authorized distributors.

- System Requirements: Ensure your PC meets the necessary hardware and software requirements for optimal performance.

- Installation Steps:

- Run the installer and follow on-screen instructions.

- Activate the software using a valid serial number.

Creating a New Project

- Open CCW: Launch the software on your computer.

- New Project Setup:

- Navigate to “Project” and select “New.”

- Choose the appropriate controller model (2080-L50E-24QBB).

- Name your project and configure initial settings such as communication protocols.

Configuration of Communication Settings

To establish communication between the PC and the controller:

- Connect Hardware: Use a USB cable for initial setup or Ethernet cable for direct connection.

- Configure IP Address:

- Access the Ethernet settings in CCW.

- Assign a static IP address compatible with your network (e.g., 192.168.0.90).

- Test Connectivity:

- Use command prompt to ping the controller’s IP address to confirm successful communication.

Programming Basics

Ladder Logic Programming

Ladder Logic is one of the primary programming languages used in CCW for programming the 2080-L50E-24QBB.

Creating Ladder Logic Rungs

- Insert Rungs: Drag and drop elements from the instruction toolbox into your ladder diagram.

- Define Conditions: Set conditions for input/output operations using contacts and coils.

- Simulate Logic: Use simulation features within CCW to test your logic before deployment.

Advanced Programming Techniques

Implicit Messaging

The 2080-L50E supports implicit messaging over Ethernet/IP, allowing for efficient data exchange between devices.

- Configure Messaging Instructions: Utilize built-in instructions in CCW to set up messaging between controllers or devices.

- Monitor Messages: Use monitoring tools in CCW to track message status and troubleshoot issues.

Troubleshooting Common Issues

Connection Problems

If you encounter issues connecting to the controller:

- Verify cable connections (USB/Ethernet).

- Check IP configurations on both PC and controller.

- Ensure that firewall settings allow CCW access.

Software Compatibility

Ensure that you are using a compatible version of CCW that supports the 2080-L50E-24QBB model:

- Check Rockwell Automation’s compatibility resources if you face issues with older versions.

Practical Applications

Industrial Automation Projects

The 2080-L50E-24QBB is widely used in various industrial applications, including:

- Manufacturing Processes: Automating assembly lines with real-time monitoring capabilities.

- Water Treatment Facilities: Controlling pumps and valves based on sensor inputs.

- Building Automation Systems: Managing HVAC systems efficiently.

Case Studies

Manufacturing Efficiency Improvement

A case study highlighted how a manufacturing plant utilized the 2080-L50E-24QBB to streamline its assembly line, resulting in a 20% increase in productivity through better control of machine operations.

Smart Building Management

Another application involved integrating multiple 2080-L50E controllers in a smart building setup, allowing centralized control over lighting, HVAC, and security systems via Ethernet/IP communication.

Future Trends in PLC Programming

As technology evolves, so does PLC programming:

Integration with IoT

The future of PLCs like the 2080-L50E includes greater integration with Internet of Things (IoT) devices, enabling remote monitoring and control through cloud platforms.

Enhanced User Interfaces

Improvements in user interfaces within programming environments like CCW will make it easier for engineers to develop complex control strategies without extensive training.

Conclusion

The 2080-L50E-24QBB programming software, primarily through Connected Components Workbench, offers a powerful platform for developing automation solutions across various industries. Its robust features and flexibility make it an ideal choice for modern industrial applications. As technology progresses, embracing these advancements will be crucial for optimizing automation processes and achieving greater efficiency in operations.