SolidWorks CNC CAD software is a powerful tool used in the manufacturing and design industries, enabling engineers and designers to create intricate designs that can be directly translated into CNC (Computer Numerical Control) machining operations. This article explores various aspects of SolidWorks CNC CAD software, its integration with CAM (Computer-Aided Manufacturing) solutions, and its applications across different industries.

Understanding SolidWorks CAD Software

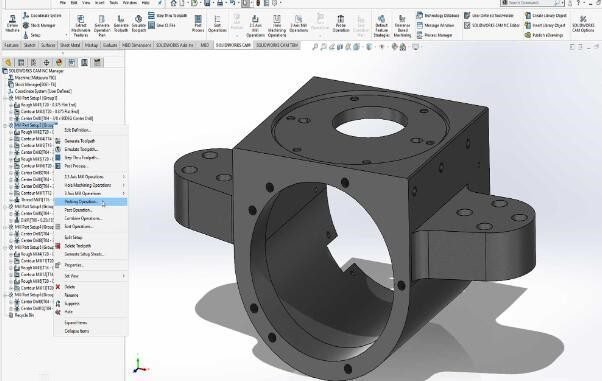

SolidWorks is a robust 3D CAD software widely used for product design and engineering. It provides a comprehensive suite of tools that allow users to create detailed 3D models and assemblies. The software’s user-friendly interface makes it accessible to both beginners and experienced professionals.

Key Features of SolidWorks

- 3D Modeling: Create complex shapes and assemblies with ease.

- Parametric Design: Modify designs dynamically by changing parameters.

- Simulation: Test designs under real-world conditions using simulation tools.

- Collaboration Tools: Facilitate teamwork through cloud-based solutions.

The Role of CNC in Manufacturing

CNC machining is a manufacturing process that uses programmed computer software to control the movement of machinery. This technology allows for high precision and repeatability in producing parts from various materials such as metal, plastic, and wood.

Benefits of CNC Machining

- Precision: High accuracy in part production.

- Consistency: Uniformity in manufacturing processes.

- Efficiency: Reduced production time and labor costs.

Integrating SolidWorks with CAM Solutions

To streamline the transition from design to manufacturing, SolidWorks integrates seamlessly with various CAM solutions like SolidCAM and SOLIDWORKS CAM. These integrations allow for direct communication between CAD designs and CNC machines.

SolidCAM Overview

SolidCAM is an integrated CAM solution that operates directly within the SolidWorks environment. It offers a range of functionalities designed to enhance machining efficiency.

Key Features of SolidCAM

- iMachining Technology: Reduces machining time by up to 70% while extending tool life.

- Full Associativity: Changes made in the CAD model automatically update tool paths.

- Advanced Machine Simulation: Provides realistic simulations of machining operations.

SOLIDWORKS CAM Capabilities

SOLIDWORKS CAM is built on industry-standard CAMWorks technology, providing powerful automation tools for CNC programming. It allows users to prepare designs for manufacturability early in the development cycle.

Features of SOLIDWORKS CAM

- Automatic Feature Recognition: Identifies machinable features automatically.

- Rules-Based Machining: Enhances programming efficiency by applying predefined rules.

- Tolerance-Based Machining: Utilizes tolerances from CAD models to optimize machining processes.

Applications Across Industries

SolidWorks CNC CAD software finds applications in various sectors, including aerospace, automotive, medical devices, and consumer products. Each industry benefits from the precision and efficiency offered by CNC machining.

Aerospace Industry

In aerospace, precision is paramount. SolidWorks enables engineers to design complex components that meet stringent safety standards while CAM solutions ensure efficient production processes.

Automotive Industry

The automotive sector utilizes SolidWorks for designing parts like engine components and chassis. The integration with CNC machining allows for rapid prototyping and production of high-quality parts.

Medical Devices

Medical device manufacturers rely on SolidWorks to design intricate devices such as implants and surgical instruments. The ability to simulate real-world conditions ensures that products meet regulatory requirements.

Consumer Products

From electronics to household items, consumer product designers use SolidWorks to create innovative designs that can be efficiently manufactured using CNC technology.

Advantages of Using SolidWorks CNC CAD Software

The integration of SolidWorks with CNC capabilities offers numerous advantages:

- Streamlined Workflow: Reduces the time between design and production.

- Cost Savings: Minimizes waste through precise machining processes.

- Enhanced Collaboration: Facilitates communication between design and manufacturing teams.

Training and Support for Users

To maximize the benefits of SolidWorks CNC CAD software, users can access various training resources:

Online Courses

Many platforms offer online courses covering both basic and advanced features of SolidWorks and its CAM integrations.

Community Forums

Engaging with community forums allows users to share experiences, ask questions, and learn from one another.

Technical Support

SolidWorks provides technical support services to assist users with any issues they may encounter during their projects.

Future Trends in CNC Machining with SolidWorks

As technology evolves, the future of CNC machining integrated with SolidWorks looks promising:

Automation and AI Integration

The incorporation of artificial intelligence into CNC programming will enhance efficiency and reduce human error in manufacturing processes.

Enhanced Simulation Capabilities

Future versions of SolidWorks may include more advanced simulation tools that provide deeper insights into machining processes before actual production begins.

Sustainability Practices

With increasing emphasis on sustainability, future developments may focus on reducing energy consumption and material waste in CNC operations.

Conclusion

SolidWorks CNC CAD software represents a vital component in modern manufacturing processes. Its integration with advanced CAM solutions like SolidCAM and SOLIDWORKS CAM enhances productivity while ensuring precision in part production. As industries continue to evolve, leveraging these technologies will be crucial for maintaining competitiveness in the global market.